Ensuring Consistency: The Role of Industrial Mixers in Chemical Hygiene Production

Introduction to Chemical Hygiene Production

Consistency is a non-negotiable standard in chemical hygiene production, which includes the manufacturing of cleaning agents, disinfectants, and sanitizers for environments ranging from healthcare settings to industrial sites. Whether formulated for use in sterile operating rooms or for floor care in warehouses, these products must perform reliably under a variety of challenging conditions—and any lapse in quality can have serious implications for both public health and the business’s reputation. Achieving predictable and repeatable results helps ensure that products are safe, efficient, and compliant with regulatory mandates, such as those imposed by OSHA, the EPA, or global quality standards. At the heart of this consistency is the use of advanced equipment, particularly the industrial mixer for chemicals, which is crucial in ensuring that every batch meets quality expectations and that no critical process variables are overlooked during the manufacturing process.

Successful chemical hygiene manufacturing demands careful formulation and precise blending of active ingredients. Ingredients such as surfactants, solvents, and disinfectant compounds must be introduced in carefully measured amounts and combined under optimized conditions. Even minor variations in composition can compromise a cleaning product’s effectiveness or violate safety standards, resulting in severe consequences such as product recalls or liability claims. Leveraging robust, well-calibrated machinery ensures the uniform incorporation of ingredients, thorough mixing throughout the vessel, and complete dissolution of powders or liquid blends, thereby upholding critical performance characteristics across high-volume production runs. Automated blending systems also facilitate documentation and tracking, essential for both traceability and quality assurance.

The Critical Role of Industrial Mixers

Industrial mixers do far more than combine raw materials. They create the homogeneous mixtures necessary for potent, stable, and shelf-ready chemical hygiene products, ensuring that every drop or scoop delivers the intended level of cleaning or disinfection. Homogeneity is crucial for product safety and effective dosing—especially for concentrated disinfectants, where improper mixing can lead to underperforming surface sterilization or, conversely, excessive chemical residues. These mixers standardize ingredient integration, minimize separation, and maintain product dependability—cornerstones of successful and compliant manufacturing. By automating and controlling the mixing process, manufacturers reduce the margin for human error and streamline production pipelines for greater scalability, faster throughput, and lower operating costs compared to manual blending approaches.

The implementation of programmable controls and sensor technologies in modern mixers provides valuable insights about digital mixers. Each blend can be recorded, monitored, and repeated with exceptional accuracy, meeting customer and regulatory demands for documented consistency and providing a crucial paper trail for audits. Troubleshooting and process improvement are greatly simplified when variables such as mixing speed, ingredient addition, and temperature are all digitally tracked.

Types of Industrial Mixers Used

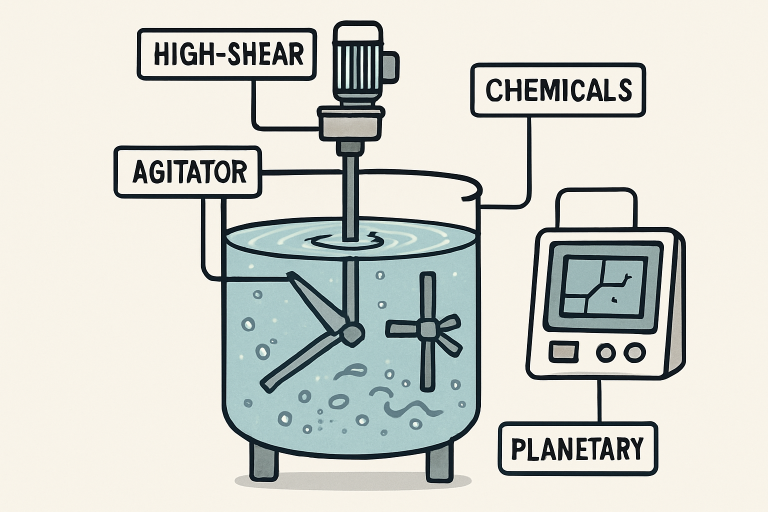

- High-Shear Mixers: Essential for breaking down particles and forming emulsions, high-shear mixers evenly disperse solids and liquids to produce stable, high-quality mixtures. They’re particularly valuable for hygiene products that rely on fine, homogenous blends, such as hand sanitizers, liquid soaps, and certain detergent bases, ensuring all active ingredients are suspended or dissolved appropriately.

- Agitators: Often used where gentle mixing or resuspension of particulates is required, agitators maintain solutions in a uniformly mixed state during both blending and storage, thereby preventing settling and ingredient separation. Their energy-efficient operation makes them ideal for the ongoing circulation of finished products in holding tanks or during gradual blending processes with ingredients.

- Planetary Mixers: Best suited for thick, viscous compounds such as gels and creams, planetary mixers ensure thorough mixing without leaving pockets of unmixed material, making them ideal for specialty and premium hygiene products. These mixers can handle high-viscosity formulations and are often favored for their precise control over mixing movement and their ability to work with a wide range of batch sizes.

Ensuring Product Consistency

Production consistency depends on the strict control of parameters such as mixing speed, duration, temperature, and the timing of ingredient introduction. For example, certain disinfectants require precise order and rate of addition for specific chemicals to fully activate and blend with solvents or water. Modern industrial mixers are equipped with programmable logic controllers (PLCs), which automate these variables for every batch, drastically reducing the risk of deviations and eliminating many sources of batch-to-batch variation. Automation not only enhances the reliability of the final product but also increases manufacturing throughput and repeatability—an essential advantage in meeting the rising demands for hygiene products during public health emergencies.

In an industry where efficacy, texture, and appearance dictate product acceptance, quality assurance teams rely on mixers to replicate results batch after batch. This rigorous standardization has enabled the industry to maintain customer trust in sectors such as healthcare and hospitality, where cleaning efficacy can significantly impact public health outcomes and user perception. Detailed batch records facilitate certification and help meet the requirements for export to global markets.

Enhancing Safety and Compliance

Automated industrial mixers play a crucial role in enhancing workplace safety. By minimizing manual handling of raw materials and utilizing enclosed systems, they reduce workers’ exposure to hazardous substances and lower the likelihood of spills, splashes, and airborne contaminants. Hazardous fumes can be effectively contained and extracted, while batch ingredients can be added through sealed feed systems, further reducing on-site exposure. Adhering to established safety and cleanliness protocols, such as those detailed in the WHO Good Manufacturing Practice (GMP) standards, ensures that these processes meet global health and quality benchmarks. Equipment designed with easy-clean surfaces and sealed chambers helps prevent cross-contamination, which is both a health and regulatory concern in chemical production. Many mixers now feature designs that facilitate rapid and thorough cleaning between batches, ensuring a fast changeover and continued compliance with GMP guidelines.

Technological Advancements in Mixing Equipment

The introduction of Industry 4.0 concepts has significantly evolved the capabilities of mixing technology in chemical hygiene production. Integrated sensors and IoT connectivity enable real-time monitoring of variables such as viscosity, temperature, energy consumption, and even ingredient levels within hoppers or tanks. Data from these sensors is collected and analyzed for predictive maintenance, allowing for proactive repairs before breakdowns cause costly production delays. Such predictive analytics not only preserve equipment longevity but also help optimize mixing cycles, reduce waste, and support quality assurance initiatives. As factories become smarter, equipment efficiency and uptime are maximized, aligning with the goals of sustainable, high-output manufacturing while supporting environmental and business objectives.

Conclusion

Industrial mixers are at the core of consistent, compliant, and high-quality chemical hygiene production. Their automated controls, capacity for uniform blending, and advanced safety features make them indispensable for manufacturers looking to remain competitive and maintain industry-leading standards. As technology and regulatory requirements continue to evolve, investing in the right industrial mixer for chemicals is crucial for manufacturers who aim to exceed industry standards, drive operational efficiencies, ensure employee and consumer safety, and deliver lasting value to their markets.

FOLLOW US ON FACEBOOK

RECENT POSTS

TAGS

About The Memory Hole

You've reached TheMemoryHole.org! A diverse lifestyle blog with content on a variety of different topics to help you define and live the life you want to live! Thanks for stopping by!

Copyright © The Memory Hole. All rights reserved.