Oil water separators are a vital part of the wastewater treatment process. They separate waste from clean water to reduce contamination and save money on sewage disposal costs.

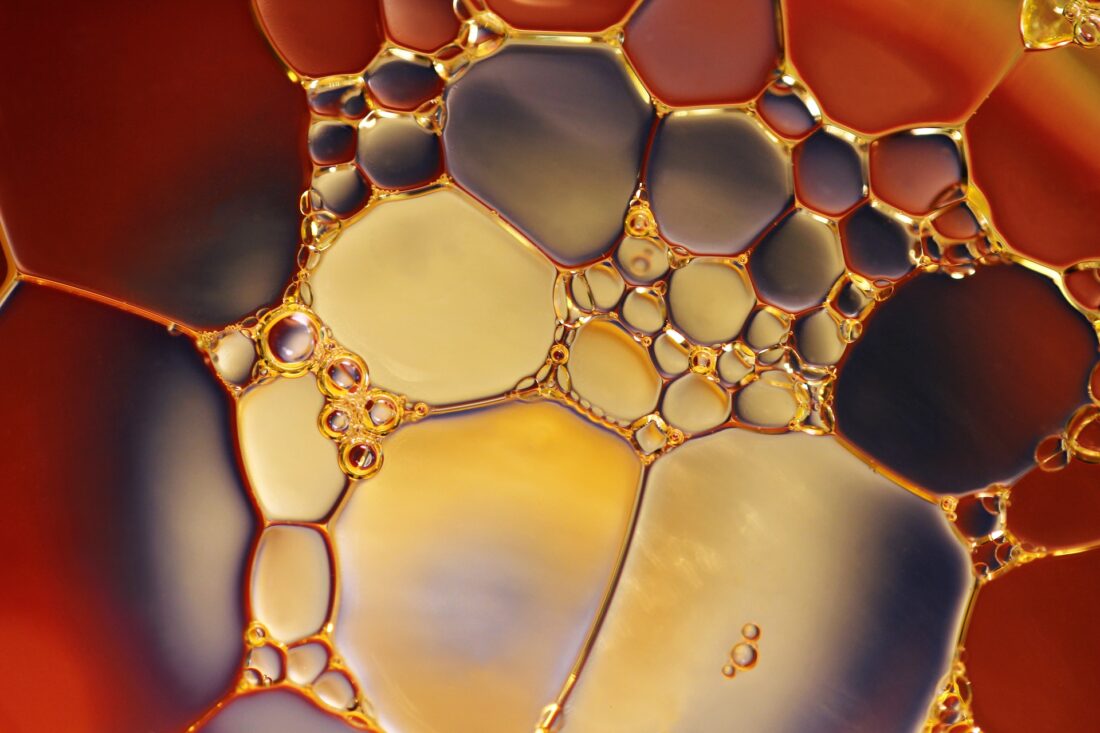

They work by separating the oil and suspended solids from wastewater using the physical principle of density. It means that oil is lighter than water and floats to the top.

Invest in a high-quality separator

Oil water separators are critical to any lubricated compressed air production system. They allow your facility to comply with environmental regulations and reduce the cost of sludge disposal.

Investing in a high-quality separator will ensure your system runs smoothly and efficiently. It will also save you money on equipment replacement and maintenance.

In addition to separating oil from wastewater, oil water separators North Carolina can be used to de-water waste streams and recover valuable oils. As a result, it can lead to higher revenue. It can also reduce the need to haul contaminated waste to landfills.

Invest in a high-quality skimmer

Skimmers are a great way to keep your pool clean and debris-free. They also help to keep your filter pump running smoothly.

Depending on the type of skimmer, you may need to spend a little money upfront, but this will be worth it in the long run. First, consider how much time you spend manually skimming your pool to see if investing in a high-quality product is worth it.

Suitable oil-water separators resist clogs and remove most oil particles from the liquid. As a result, they will save you operating costs and reduce your risks of injury or contamination.

Invest in a high-quality pump

A quality pump is an essential part of a successful oil-water separator system. It moves water from a holding tank to the oil separator.

A poor-quality pump could cause turbulence in the water stream. In addition, it would result in oil droplets that are too small to be separated easily.

A high-quality pump can also help prevent the buildup of sludge, which could interfere with the separator’s performance.

Invest in a high-quality control system

Investing in a high-quality control system is one of the best ways to save time and money on the production line. Not only does it prevent costly mistakes, but it also helps you build trust with your customers.

A quality control system is a must-have for any oil water separator manufacturer. A product can be made better or worse depending on its use. The best part is that it’s a small cost to implement. The type of innovation will pay off in spades down the road.

Invest in a high-quality control panel

A high-quality control panel is a must-have for any oil-water separator. It helps you control and monitor the system to ensure it operates efficiently. It can also help you avoid steep fines or being held at port for a faulty system.

Selecting a quality control panel designed and developed under performance specifications and robust and reproducible QC testing is essential. In addition, it should be able to test the product at all stages of its manufacturing process to ensure it performs as expected.

Invest in a high-quality control system

Investing in a high-quality control system is essential to ensure that your separators are working efficiently. A good quality control system will help you identify defects and take corrective actions.

It will also help you get customer feedback on their experiences with your products and services. This feedback can help you improve your business processes and increase customer satisfaction.

FOLLOW US ON FACEBOOK

RECENT POSTS

TAGS

About The Memory Hole

You've reached TheMemoryHole.org! A diverse lifestyle blog with content on a variety of different topics to help you define and live the life you want to live! Thanks for stopping by!

Copyright © The Memory Hole. All rights reserved.